Top 10 Power Elevated Work Platform Training Tips for Enhanced Safety

In the construction and industrial sectors, the use of Power Elevated Work Platforms (PEWPs) has significantly increased due to their effectiveness in reaching heights safely and efficiently. However, this rise in usage comes with additional responsibilities regarding operator safety and comprehensive training. According to the Occupational Safety and Health Administration (OSHA), falls remain one of the leading causes of workplace fatalities, making adequate Power Elevated Work Platform Training absolutely critical. In fact, statistics show that nearly 20% of all serious injuries in the workplace are attributed to falls from elevated surfaces.

To mitigate these risks, organizations must prioritize the development of robust training programs. An effective training regimen not only enhances the operator's skills but also fosters a culture of safety that permeates the entire workforce. The National Institute for Occupational Safety and Health (NIOSH) emphasizes that well-designed training programs can lead to a significant reduction in accidents and injuries associated with elevated work platforms. By implementing best practices in Power Elevated Work Platform Training, employers can create a safer working environment, ultimately translating to increased productivity and lowered operational costs. In this article, we will outline the top 10 training tips that can enhance safety and ensure that all operators are well-prepared to navigate the challenges that come with working at heights.

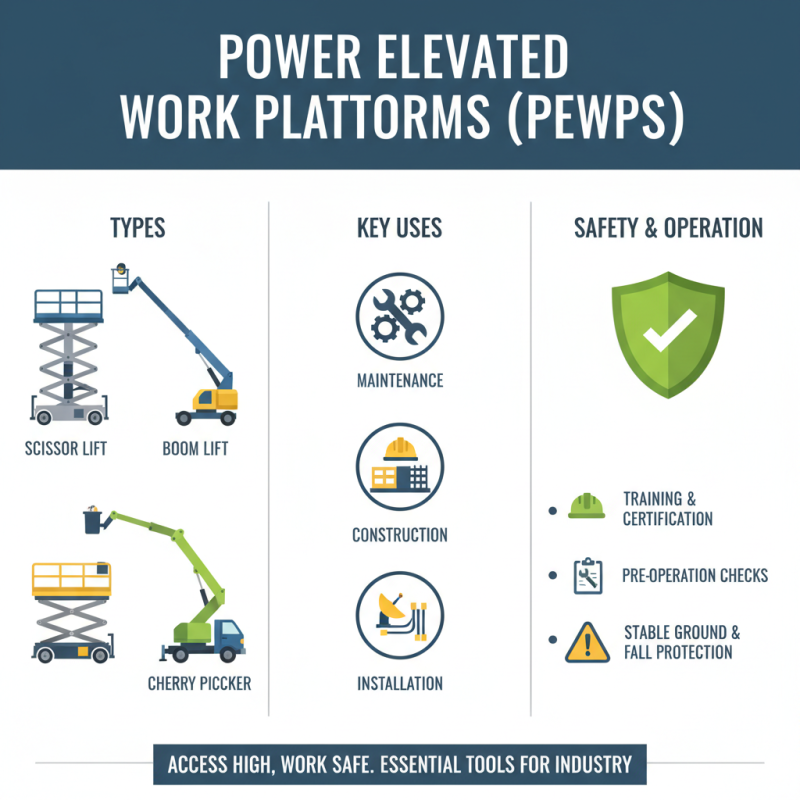

Understanding Power Elevated Work Platforms: An Overview

Power Elevated Work Platforms (PEWPs) are essential tools in various industries, providing workers the ability to reach high and difficult-to-access areas safely. These platforms, which include scissor lifts, boom lifts, and cherry pickers, are designed to elevate personnel for tasks such as maintenance, construction, or installation. Understanding the mechanics and proper operation of these platforms is critical to ensuring both effectiveness and safety in the workplace.

One crucial tip for enhancing safety when using PEWPs is conducting thorough pre-use inspections. Always check the equipment for any signs of damage or wear, including hydraulic systems and safety features. Operators should familiarize themselves with the user manual, which contains important details about load limits and operational guidelines. Another important aspect is providing proper training to all operators, ensuring they understand not only how to operate the machinery but also the potential hazards associated with their work environment.

Additionally, establishing a clear communication plan among team members can significantly reduce risks. Utilizing hand signals or two-way radios ensures that operators and ground personnel can easily convey important information during operations. It’s also vital to create a safe work zone by keeping the area free of obstacles and ensuring that all workers are aware of the ongoing activities around the platform. By focusing on these practices, organizations can enhance safety measures while utilizing power elevated work platforms effectively.

The Importance of Safety Training for Work Platform Operators

The Importance of Safety Training for Work Platform Operators cannot be overstated, especially given the high-risk nature of operating elevated work platforms. Ensuring that operators are well-trained significantly reduces the likelihood of accidents and injuries on the job site. Comprehensive training equips operators with the knowledge necessary to understand the mechanics of the equipment, identify potential hazards, and implement safety protocols effectively. Ultimately, this not only protects the individuals involved but also promotes a culture of safety within the workplace.

To enhance safety, it’s crucial to incorporate specific training tips. First, operators should be trained to perform thorough pre-operation inspections to identify any malfunctions or safety issues before starting work. This proactive step can prevent accidents and ensure that equipment is in optimal condition. Furthermore, continuous education on updated safety regulations and practices is essential, as it fosters awareness of changing standards and promotes best practices among operators. Finally, practical hands-on training, alongside theoretical knowledge, allows operators to gain valuable experience in navigating challenging work environments safely, facilitating better decision-making during real-world operations.

Key Components of Effective Work Platform Training Programs

Effective work platform training programs are essential for ensuring safety and productivity when using power elevated work platforms. Key components of these programs should focus on the specific needs of the workforce and the type of equipment being utilized. First and foremost, comprehensive training should cover the operational aspects of the equipment, including controls, stability, and load capacity, ensuring that workers are well-versed in how to handle the machinery safely. Additionally, hands-on training is critical, as it allows operators to practice in a controlled environment, reinforcing their skills and boosting their confidence.

Moreover, a strong emphasis on safety standards and best practices is vital to prevent accidents and injuries. Training programs must include detailed information on personal protective equipment (PPE), hazard recognition, and emergency protocols. Regular safety drills and assessments should be integrated into the training curriculum to keep safety at the forefront of workers' minds. By fostering an ongoing culture of safety and providing continuous education, organizations can enhance the effectiveness of their training programs, ensuring that all employees are equipped with the knowledge and skills necessary to operate elevated work platforms safely.

Common Hazards Associated with Elevated Work Platforms and Mitigation Strategies

Working at heights using elevated work platforms (EWPs) can pose significant hazards that require thorough risk assessment and management. Common hazards include falls from heights, which are a leading cause of serious injuries in the workplace. To mitigate this risk, it is essential to ensure that all operators are well-trained in using fall protection systems. This includes understanding how to properly wear harnesses and use guardrails effectively, as well as being familiar with the platform's safety features.

Another critical hazard associated with EWPs is the risk of tipping over, often due to unstable ground or improper loading. To address this, operators should conduct thorough site assessments prior to operation, ensuring the ground is stable and level. Load limits should always be adhered to, and operators must be trained in weight distribution and load securing techniques. Frequent inspections and maintenance of the equipment are also crucial in preventing mechanical failures that could lead to accidents. By prioritizing safety training and hazard awareness, workers can significantly reduce the risks associated with using elevated work platforms.

Top 10 Power Elevated Work Platform Training Tips for Enhanced Safety

| Tip Number | Training Tip | Common Hazards | Mitigation Strategies |

|---|---|---|---|

| 1 | Conduct a pre-use inspection | Mechanical failure | Ensure all components are functioning properly |

| 2 | Provide comprehensive training | Operator error | Training on equipment operation and safety procedures |

| 3 | Use proper personal protective equipment (PPE) | Falling objects | Ensure all personnel wear hard hats and safety gear |

| 4 | Establish a safety plan | Accidents due to workplace hazards | Create a response plan for emergencies |

| 5 | Implement fall protection systems | Falling from height | Use guardrails, safety nets, or harnesses |

| 6 | Maintain clear communication | Misunderstandings during operation | Use radios or hand signals |

| 7 | Train for specific site conditions | Environmental hazards | Assess and adapt to site-specific challenges |

| 8 | Enforce equipment load limits | Overloading | Regularly check and enforce load capacities |

| 9 | Practice emergency procedures | Inadequate response in emergencies | Conduct regular drills and reviews |

| 10 | Schedule regular maintenance | Equipment malfunction | Follow a strict maintenance schedule |

Best Practices for Conducting Safe Work Platform Operations

Ensuring safety in elevated work platform operations involves adhering to best practices that significantly reduce the risk of accidents and injuries. According to the U.S. Bureau of Labor Statistics, falls from elevated work surfaces contribute to a substantial number of workplace injuries, accounting for 33% of construction-related fatalities. Therefore, comprehensive training programs that emphasize hazard recognition and safe operating procedures are essential for all workers involved with power elevated work platforms.

One key practice is conducting thorough pre-operation inspections of the equipment, which should encompass checks of hydraulic systems, stabilizers, and emergency features. A report by the National Institute for Occupational Safety and Health (NIOSH) highlights that over 50% of workplace accidents could be mitigated through regular maintenance and proper inspections. Furthermore, employing a buddy system during operations can enhance communication and ensure immediate assistance in case of an emergency. Training should also include simulations and drills to prepare workers for various scenarios, fostering an environment where safety is prioritized and engrained in the workplace culture.

Top 10 Power Elevated Work Platform Training Tips for Enhanced Safety

Related Posts

-

What is Ipaf Mobile Platform Training and Why is it Important for Safety

-

How to Enhance Safety with Mobile Elevated Work Platform Training

-

Ultimate Guide to Ensuring Safety in Elevated Work Platform Training with Data Driven Insights

-

How to Master Power Elevated Work Platform Training for Enhanced Safety and Efficiency

-

Mastering Mobile Elevated Platform Safety: Essential Training for Operators

-

Innovative Examples of Climbing Platforms Enhancing Safety and Efficiency in Industrial Applications