Top 10 Mobile Elevated Work Platform Types Explained

In the world of construction and industrial work, understanding "Mobile Elevated Work Platform Types" is vital. Mark Johnson, an industry expert with over 20 years of experience, once stated, "Choosing the right platform can make or break a project." This emphasizes the importance of selecting appropriate equipment.

Mobile elevated work platforms (MEWPs) come in various forms, each designed for specific tasks. Whether for indoor maintenance or outdoor construction, these types support worker safety and efficiency. From scissor lifts to boom lifts, knowing the options available is essential. Many people overlook how the choice impacts productivity and safety.

Yet, the industry faces challenges. Often, workers don’t receive adequate training on different MEWP types. This can lead to unsafe practices and inefficiencies. Awareness of the various Mobile Elevated Work Platform Types helps mitigate these risks. As more people recognize their significance, the conversation around safety and equipment choice continues to evolve.

Overview of Mobile Elevated Work Platforms (MEWPs)

Mobile Elevated Work Platforms (MEWPs) are vital tools in various industries. They provide safe access to elevated work areas. According to the International Powered Access Federation (IPAF), the global MEWP market is expected to reach $9 billion by 2025. This growth reflects their importance across sectors like construction, maintenance, and events.

MEWPs come in various types, each tailored for specific tasks. Scissor lifts, for example, are excellent for indoor projects. They offer stable platforms for workers. However, they can struggle on uneven ground. Boom lifts, on the other hand, provide reach and flexibility. They are often used in outdoor settings. But with that flexibility comes the need for strict safety measures.

One crucial aspect is operator training. Inadequate training can lead to accidents. A report by the U.S. Bureau of Labor Statistics shows that over 20% of MEWP-related injuries stem from improper use. Regular inspections also play a vital role. Neglecting maintenance can result in unexpected failures. Employing a culture of safety is essential for all MEWP operations.

Top 10 Mobile Elevated Work Platform Types Explained

| Platform Type | Max Working Height (ft) | Platform Capacity (lbs) | Drivability |

|---|---|---|---|

| Scissor Lift | 50 | 1500 | Indoor/Outdoor |

| Boom Lift | 60 | 500 | Indoor/Outdoor |

| Telehandler | 50 | 8000 | Outdoor |

| Aerial Work Platform | 30 | 1000 | Indoor |

| Self-Propelled Lift | 40 | 1000 | Indoor/Outdoor |

| Articulating Boom Lift | 40 | 500 | Indoor/Outdoor |

| Trailer Mounted Lift | 50 | 600 | Outdoor |

| Personnel Lift | 20 | 350 | Indoor |

| Compact Scissor Lift | 30 | 800 | Indoor |

| Van-Mounted Lift | 40 | 500 | Outdoor |

Types of Mobile Elevated Work Platforms and Their Uses

Mobile Elevated Work Platforms (MEWPs) come in various types, each suited for specific tasks. Common types include scissor lifts, boom lifts, and personnel lifts. Scissor lifts are ideal for vertical tasks. They provide a stable platform for work at heights, often used in warehouses. Boom lifts are more versatile, offering horizontal reach. They are essential for outdoor tasks, such as tree maintenance. Personnel lifts are compact, perfect for tight spaces.

Reports show that the global MEWP market is expected to grow significantly. Market research indicates a projected increase of 8% annually by 2025. This growth highlights the rising demand for safe and efficient work at heights. Industries increasingly prefer these platforms over traditional ladders and scaffolds. They improve safety and productivity on construction sites. However, operators must be well-trained to avoid accidents.

Tips: Always assess the working environment before choosing a MEWP. Check the ground conditions and overhead obstacles. Regular maintenance can prevent equipment failures, reducing downtime. Operators should engage in safety training to enhance awareness and minimize risks. Investing in proper training and maintenance leads to better outcomes in tasks involving MEWPs.

Top 10 Mobile Elevated Work Platform Types and Their Uses

This chart illustrates the percentage of different types of Mobile Elevated Work Platforms (MEWPs) used in various industries. Scissor lifts are the most commonly used, followed by boom lifts and cherry pickers. Each type serves specific requirements based on height and workspace conditions.

Key Features of Different MEWPs Explained

Mobile Elevated Work Platforms (MEWPs) come in various types, each with specific features that cater to different working conditions. According to a recent industry report, the global MEWP market is expected to grow substantially, driven by urbanization and infrastructure development.

Scissor lifts are popular for their vertical reach and stability. They are perfect for indoor tasks where floor conditions are smooth. Their versatility in tight spaces is a significant advantage.

Boom lifts, on the other hand, are designed for jobs that require outreach. They allow operators to access hard-to-reach places. Many users appreciate their flexibility, but some struggle with maneuverability in crowded sites. Forklifts equipped with lift capabilities provide dual functionality, but operators must ensure proper training to avoid accidents. Reports indicate that improper use accounts for a large percentage of MEWP-related incidents.

Vertical lifts are ideal for indoor applications but can be limiting outdoors. These units often lack the outreach needed for expansive projects. Safety features vary widely, with models having fall protection systems being essential in high-risk environments.

Understanding these nuances is critical for safe operations. Balancing efficiency and safety is a constant challenge for users. The right choice can enhance productivity but requires careful consideration of workplace conditions.

Safety Considerations When Using MEWPs

Mobile Elevated Work Platforms (MEWPs) are essential in various industries. However, using them comes with significant safety considerations. According to the International Powered Access Federation (IPAF), improper use of MEWPs leads to approximately 30% of all fatalities in the aerial work platform sector. This alarming statistic highlights the need for strict adherence to safety protocols.

Training is critical. Operators must undergo proper training, as untrained personnel can lead to accidents. A study by the U.S. Bureau of Labor Statistics found that nearly 50% of MEWP-related injuries involved individuals who had not received formal training. Additionally, regular equipment inspections can prevent mechanical failures. In 2021, a survey indicated that 15% of MEWP incidents occurred due to equipment malfunction. These failures can often be avoided through diligent maintenance and safety checks.

Worksite conditions also play a vital role in safety. Environmental factors like wind speed and ground stability can impact MEWP operations. A report from the Occupational Safety and Health Administration noted that many operators do not assess these conditions adequately. Inadequate risk assessments can lead to dangerous situations. Thus, a culture of safety is essential in any organization utilizing MEWPs. Continuous education and strict adherence to safety measures should be prioritized.

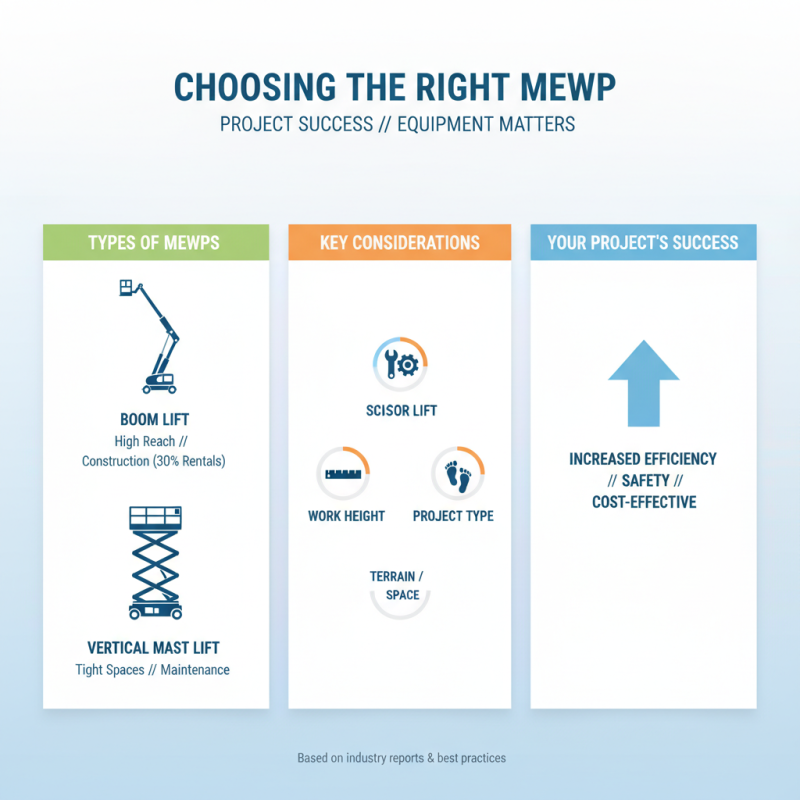

Choosing the Right MEWP for Your Project Needs

Choosing the right Mobile Elevated Work Platform (MEWP) is crucial for your project's success. MEWPs come in various types, each with unique advantages. The decision should be based on the specific needs of your project. For example, if you need to lift workers high for construction work, a boom lift may be ideal. Reports suggest that boom lifts account for over 30% of MEWP rentals in the industry.

When selecting a MEWP, consider the working environment. Indoor projects often require compact models with zero emissions. According to industry data, around 40% of operators prioritize electric MEWPs for indoor use. In contrast, outdoor tasks may need diesel-powered options for better durability. The terrain can also impact your choice. Uneven surfaces may necessitate scissor lifts with wider bases for stability.

Safety must be a primary concern. Operators should always undergo proper training. Surprisingly, almost 25% of accidents occur due to operator error. Regular maintenance is essential, yet many companies overlook it. Industry statistics indicate that more than 20% of MEWPs malfunction due to poor upkeep. Every choice and oversight can significantly impact productivity and safety. Make informed decisions to enhance your project's outcomes.

Related Posts

-

Top Mobile Elevated Work Platform Manufacturers in China at the 137th Canton Fair

-

Championing Excellence in Mobile Elevated Work Platforms Made in China

-

5 Key Features to Consider for the Best Mobile Aerial Work Platform

-

What is the Advantage of Using the Best Mast Climbing Platform for Construction Efficiency

-

Exploring Innovative Alternatives to Best Mast Climbing Work Platforms Mewps

-

Innovative Examples of Climbing Platforms Enhancing Safety and Efficiency in Industrial Applications