Ultimate Tips for Using Mast Climbing Work Platforms Mewps?

In the world of construction, safety and efficiency are paramount. Mast Climbing Work Platforms Mewps are becoming increasingly popular for high-rise buildings. John Smith, a renowned expert in aerial work platforms, once said, "Using Mewps effectively can change the entire landscape of a project." His words highlight the significance of mastering these tools.

Mast Climbing Work Platforms Mewps offer unique advantages. They allow workers to reach high areas safely and efficiently. However, improper use can lead to accidents. It’s crucial to understand the limits and capabilities of these platforms. Many operators underestimate the maintenance needed for optimal performance.

Training is essential for workers using Mast Climbing Work Platforms Mewps. Regular evaluations can prevent mistakes. Despite their effectiveness, reliance solely on Mewps is not wise. A comprehensive approach that includes alternative methods can enhance safety. Paying attention to details can save lives. It’s clear that continuous improvement and awareness make a difference.

Understanding Mast Climbing Work Platforms: A Comprehensive Overview

Mast climbing work platforms (MCWPs) are gaining popularity in the construction industry. They provide a versatile solution for projects requiring elevated workspaces. According to the International Association of Scaffold Manufacturers (IASM), MCWPs can increase productivity by over 30% compared to traditional scaffolding methods. These platforms allow quick vertical movement and provide safer working conditions. Workers can access various heights with minimal setup time.

Despite their benefits, challenges remain. Operators must be well-trained to avoid accidents. The Work Equipment Regulations stipulate that proper maintenance is vital. Neglecting this could lead to mechanical failures and jeopardize safety. Data from the National Safety Council shows that falls account for about 33% of construction-related fatalities. Using MCWPs correctly could significantly reduce these figures, but awareness and training are crucial.

Incorporating technology can enhance the effectiveness of mast climbing platforms. Some platforms now come with integrated safety systems, including load sensors. However, reliance on technology can lead to complacency. Regular inspections are still necessary to ensure all components function correctly. Disregarding these basic checks can result in catastrophic outcomes, highlighting the complexity of safety in the construction realm. Each project requires a tailored approach to fully leverage the benefits of MCWPs while addressing inherent risks.

Key Safety Precautions When Using Mewps for Elevated Work

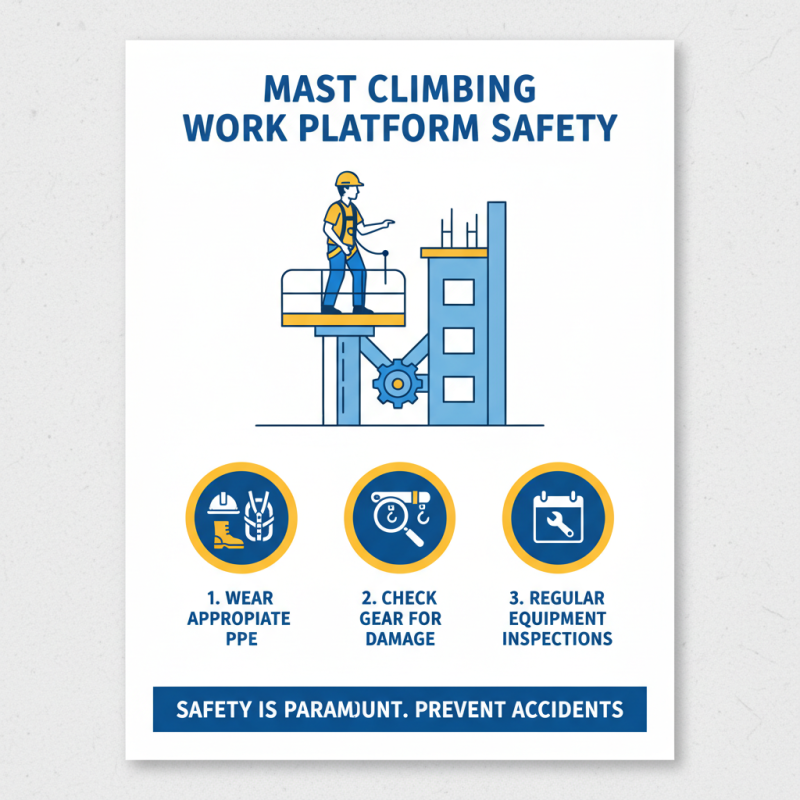

When using mast climbing work platforms, safety is paramount. Workers should always wear appropriate personal protective equipment (PPE). Hard hats, harnesses, and non-slip shoes are essential. Each worker must check their gear for signs of wear or damage. Regular inspections of the equipment can prevent accidents.

Before starting any elevated work, it's crucial to ensure the platform is stable. Check the ground conditions and the structural integrity of nearby buildings. Clear any debris that could pose a risk when working at heights. Communication among team members is vital. Use hand signals or radios to stay in touch. This helps avoid misunderstandings that could lead to serious injuries.

Attention to detail is key. Train workers on emergency procedures in case of equipment failure. Encourage them to reflect on their experiences for improvement. A near-miss should never be overlooked. Each incident can teach valuable lessons in safety. Prioritize creating a culture of safety where everyone feels responsible. This not only protects individuals but also enhances overall productivity.

Best Practices for Operating Mast Climbing Platforms Efficiently

Operating mast climbing work platforms efficiently requires careful planning and awareness. Start by ensuring that all operators are certified and understand the platform’s capabilities. Regularly inspect the equipment before use. Look for wear and tear that could lead to malfunctions. It’s essential to communicate with team members clearly. Use hand signals if necessary. This helps maintain safety and efficiency on-site.

When working at height, always secure tools and materials. They should not create hazards for those below. Take regular breaks to keep your team alert and focused. Fatigue can lead to mistakes. It's important to adjust your workflow if you notice any delays or inefficiencies. Reflect on what could be done better. This can include improving schedules or the distribution of tasks. Encourage a culture where feedback is welcome, allowing everyone to share concerns.

Ultimate Tips for Using Mast Climbing Work Platforms Mewps

This chart showcases the efficiency ratings of various practices associated with operating mast climbing platforms, measured through user feedback and operational efficiency scores. The data reflects best practices for enhancing safety and productivity when using Mewps.

Maintenance Tips for Prolonging the Life of Mewps

Maintaining mast climbing work platforms, or MEWPs, is essential for ensuring their longevity. Regular inspections are crucial. Check for any signs of wear or damage. Look closely at cables and pulleys. A small issue can turn into a major fault if ignored. Always test the functionality before each use. A quick check can save a lot of trouble later.

Cleaning is another vital part of maintenance. Dust and debris can accumulate, making parts less efficient. It’s important to keep surfaces clear and lubricated. This applies to moving parts as well. A bit of grease can go a long way in preventing rust and ensuring smooth operation. However, over-greasing can also lead to issues. Finding the right balance is key.

Training operators is not just an option; it’s necessary. A well-trained team can spot problems early. Yet, mistakes can happen. Overconfidence or neglecting guidelines may lead to accidents. Encourage open communication about safety concerns. This creates a proactive environment. Emphasizing that no one is infallible helps maintain focus on safety and efficiency.

Choosing the Right Mast Climbing Platform for Your Project Needs

When selecting the right mast climbing platform for your project, consider your specific needs. Evaluate the height and weight requirements. Not all platforms are created equal. Some may lack the necessary features for heavy-duty tasks. Think about the terrain as well. Uneven ground can affect stability.

Tips: Assess your site carefully. This means checking for obstacles and ground conditions. A clear site will lead to better operations. Always inspect the platform before each use. Understand the weight limitations. Many overlook this crucial aspect. It can lead to safety hazards.

Look at the reach of the platform. It should extend to all necessary areas of your project. Ensure there’s adequate safety equipment available. This includes guardrails and harnesses. Remember that comfort affects productivity. A cramped working space can hinder progress. Think about project timelines too. Delays can occur if the wrong equipment is chosen. It’s important to reflect on these details.

Ultimate Tips for Using Mast Climbing Work Platforms Mewps

| Aspect | Details |

|---|---|

| Load Capacity | Typically ranges from 500 kg to 1600 kg |

| Height Range | Commonly available from 10 meters to 60 meters |

| Power Source | Electric, diesel, or hybrid options available |

| Mobility | Stationary or mobile units depending on project needs |

| Applications | Construction, maintenance, and inspections for tall structures |

| Safety Features | Emergency lowering, anti-collision systems, and harness points |

| Setup Time | Typically requires 1-4 hours depending on the unit |

Related Posts

-

China's Dominance in Manufacturing: The Rise of Best Mast Climbing Work Platforms (MEWPs)

-

Exploring Innovative Alternatives to Best Mast Climbing Work Platforms Mewps

-

5 Best Reasons to Choose Mast Climbing Work Platforms Mewps for Your Next Project

-

What is a Mast Climbing System and How Does It Enhance Construction Efficiency

-

Finding the Right Supplier for Best Easy Climb Mast Climbers Your Ultimate Guide to Quality and Reliability

-

Unleashing Efficiency with the Best Mast Climbing System Examples in Modern Construction