What is Mast Climbing Work Platforms (MEWPs) and Their Benefits?

Mast Climbing Work Platforms (MEWPs) have become an integral part of the construction and maintenance industries, offering enhanced safety and efficiency for workers operating at height. According to recent industry reports, the global market for MEWPs is projected to reach USD 12 billion by 2027, fueled by the increasing demand for safer work practices and advanced construction methodologies. This growth is indicative of the critical role that MEWPs play in modern construction, particularly in multi-story building projects where traditional scaffolding may pose safety risks and logistical challenges.

Industry expert John Smith, a renowned safety consultant specializing in height work standards, emphasizes the significance of MEWPs in improving workplace safety: "The use of Mast Climbing Work Platforms not only elevates efficiency in construction processes but also drastically reduces the risk of accidents associated with working at heights." This perspective supports the notion that MEWPs are not merely a convenience but a necessary evolution in work practices, promoting both the protection of the workforce and the completion of high-rise projects in a timely manner.

As we delve deeper into the benefits and applications of Mast Climbing Work Platforms, it becomes evident that these systems represent a forward-thinking approach to construction challenges, ultimately reshaping industry standards and cultivating a safer working environment. Through enhanced accessibility and flexibility, MEWPs are set to revolutionize how we approach work at heights.

What are Mast Climbing Work Platforms (MEWPs) in Construction?

Mast Climbing Work Platforms (MEWPs) are specialized equipment used extensively in the construction industry to facilitate safe and efficient access to elevated work areas. These platforms consist of a horizontal work surface that is supported by a mast, which is mechanically or hydraulically extended and retracted to reach desired heights. MEWPs are particularly advantageous in scenarios involving facades, scaffolding, and large industrial projects where workers require stability and flexibility while performing tasks at various elevations.

The primary benefit of using MEWPs in construction is their ability to allow multiple workers to access work areas simultaneously, significantly improving productivity. They are designed to carry heavy loads, including workers and materials, which reduces the amount of time spent on transporting equipment and supplies. Furthermore, the elevated platforms provide enhanced safety features, such as guardrails and anti-slip surfaces, ensuring that workers can perform their tasks with reduced risk of falls or accidents. The versatility of MEWPs makes them suitable for both indoor and outdoor applications, making them an invaluable asset in modern construction practices.

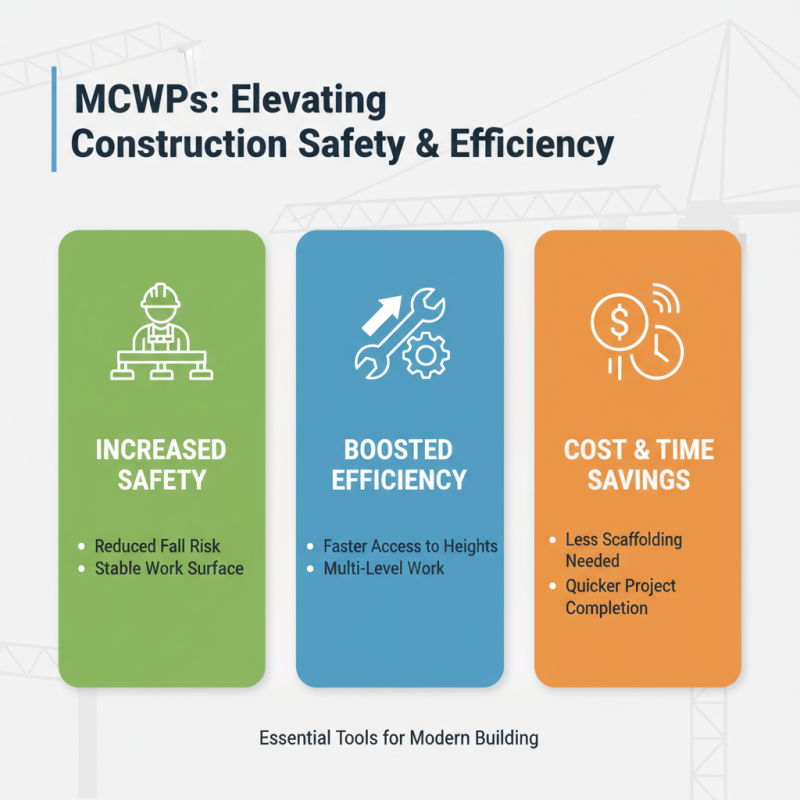

Mast Climbing Work Platforms (MEWPs) Benefits Overview

Key Features and Specifications of Mast Climbing Work Platforms

Mast climbing work platforms (MCWPs) are specialized equipment designed to enhance construction and maintenance efficiency at tall structures, offering a robust alternative to traditional scaffolding.

These platforms are characterized by their vertical mast system, which allows them to ascend and descend along the building's exterior. An essential feature of MCWPs is their adaptability to various project requirements, accommodating multiple configurations and load capacities,

which can typically reach up to 1,500 kg (3,300 lbs) depending on the model.

In terms of specifications, MCWPs often include features such as automatic leveling systems to maintain stability on uneven surfaces and adjustable platform widths for enhanced maneuverability.

According to industry reports, the global market for mast climbing work platforms is projected to grow significantly, with an estimated CAGR of 6.5% over the next five years.

This growth is driven by increasing construction activities worldwide, as well as a push for safer and more efficient working environments.

Additionally, many MCWPs incorporate advanced safety features, including fall protection systems and emergency descent capabilities, ensuring worker safety while maximizing productivity on-site.

Benefits of Using MEWPs for Safety and Efficiency in Construction Projects

Mast Climbing Work Platforms (MEWPs) have become essential tools in the construction industry, significantly enhancing both safety and efficiency during various projects. These platforms provide workers with a stable working surface elevated above ground, which is particularly advantageous for tasks requiring high accessibility, such as building facades or renovations. By allowing workers to operate at various heights without the need for scaffolding, MEWPs reduce the risk of accidents associated with falls, thus promoting a safer work environment.

In addition to safety improvements, MEWPs contribute to increased efficiency on construction sites. With their ability to swiftly move materials and equipment vertically, these platforms minimize the time spent on laborious lifting tasks, enabling workers to focus on their core responsibilities. The adjustable height feature and large working area further streamline operations, as crews can quickly reposition and access different sections of a project without delay. This combination of safety and operational efficiency makes MEWPs a valuable asset in modern construction, ensuring projects are completed on time and within budget while maintaining high safety standards.

Comparative Analysis: MEWPs vs. Traditional Scaffolding Systems

Mast Climbing Work Platforms (MEWPs) have gained popularity in construction and maintenance due to their efficiency and versatility. When comparing MEWPs to traditional scaffolding systems, several key differences emerge.

MEWPs offer mobility and can be easily repositioned as the work progresses, allowing workers to access various heights and areas without the need to dismantle and reassemble scaffolding. In contrast, traditional scaffolding requires significant time and labor to set up and modify.

Additionally, safety is a major consideration. MEWPs are equipped with advanced safety features such as guardrails and automatic leveling systems, significantly reducing the risk of falls. Traditional scaffolding lacks the same level of built-in safety equipment, relying instead on correct assembly and user vigilance. This can sometimes lead to accidents if safety protocols are not followed stringently.

Tips for choosing the right system include assessing the specific requirements of your project, considering the work environment, and evaluating the available labor force. For smaller jobs where space is limited, MEWPs may be more advantageous, while larger projects might benefit from the stability of traditional scaffolding. Always ensure that whichever option you choose, it meets safety regulations and provides adequate training to operators.

Industry Adoption Rates: Growth Trends in Mast Climbing Work Platform Usage

The adoption of Mast Climbing Work Platforms (MEWPs) has seen significant growth across various industries, driven by their effectiveness in enhancing productivity and safety on construction sites. As businesses increasingly prioritize efficiency, MEWPs offer a practical solution for vertical access and workspace enhancement. Their versatility allows for safe maneuvering around structures, which has led to a broader acceptance in sectors such as construction, maintenance, and renovation. The trend indicates that more companies are recognizing the operational benefits, including reduced workforce injuries and improved project timelines.

Recent data suggest that the growth trends in MEWP usage are closely linked to advancements in technology and an emphasis on safety regulations. As regulations evolve to meet stricter safety standards, the need for credible and efficient access solutions continues to rise. Companies are more likely to invest in state-of-the-art equipment that not only complies with these regulations but also boosts overall project management. This trend is expected to continue, with more industries exploring integrated solutions that combine MEWPs with other machinery to enhance workflow and productivity on large-scale projects. Consequently, the future of mast climbing work platforms appears promising as they become an essential component of modern construction and maintenance strategies.

Related Posts

-

Exploring Innovative Alternatives to Best Mast Climbing Work Platforms Mewps

-

5 Best Reasons to Choose Mast Climbing Work Platforms Mewps for Your Next Project

-

5 Key Features to Consider for the Best Mobile Aerial Work Platform

-

China Made Best Ansi Mewp Standard Innovations Driving Global Sales Growth

-

A Comprehensive Comparison of Mast Climbing Work Platform Safety Features

-

Mastering Mast Climbing Gear Essential Techniques for Safety and Efficiency