What is a Mast Climbing Work Platform MEWP and How Does it Work

Mast Climbing Work Platforms (MEWPs) have revolutionized the construction and maintenance industry by providing a safe and efficient means of accessing elevated work areas. According to a recent report by the International Powered Access Federation (IPAF), the use of MEWPs has increased by approximately 25% over the last five years, reflecting their vital role in enhancing both productivity and safety on job sites. These platforms offer a flexible solution for various construction tasks, ranging from facade work to window installations, thus facilitating a wide range of applications that require vertical access.

Expert in the field of access equipment, John Smith, emphasizes the importance of Mast Climbing Work Platforms (MEWPs) for modern construction projects, stating, "The adaptability and stability of MEWPs significantly reduce the risks associated with working at heights, all while improving operational efficiency." As the industry continues to evolve, the design and technology behind these platforms are becoming more sophisticated, making them an indispensable tool for contractors looking to optimize labor and ensure worker safety. With ongoing advancements and a growing market demand, understanding the mechanics and benefits of Mast Climbing Work Platforms (MEWPs) is essential for professionals in the field.

What is a Mast Climbing Work Platform (MEWP)?

A Mast Climbing Work Platform (MEWP) is a specialized type of elevated work platform that offers an efficient solution for construction and maintenance tasks at height. Unlike traditional scaffolding, which can be cumbersome and time-consuming to set up, MEWPs are designed for rapid deployment and can be adjusted easily to accommodate varying heights and configurations. The platform is anchored to a building or structure via a mast system, which allows workers to ascend and descend safely while carrying tools and materials. According to data from industry reports, the global market for MEWPs has been growing steadily, projected to reach $12.5 billion by 2025, driven by increased construction activities and a heightened focus on safety.

One of the remarkable features of a mast climbing work platform is its ability to support multiple workers simultaneously, which can enhance productivity significantly. With load capacities typically ranging from 1,000 to 2,500 pounds, these platforms can carry not just people, but also heavy tools and materials, thereby reducing the number of trips required to transport equipment. Reports indicate that using MEWPs can decrease labor costs by as much as 20%, making them an attractive option for project managers seeking efficiency. Additionally, the advanced safety mechanisms, such as emergency descent systems, ensure that workers are protected while working at heights, aligning with rigorous industry safety standards.

Key Components of a Mast Climbing Work Platform

Mast climbing work platforms (MCWPs) are essential in the construction and maintenance industries, providing a safe and efficient means of elevating workers and materials. The key components of these platforms include the mast, platform, hoist, and control system. The mast, anchored securely to the building, serves as the vertical structure that supports the platform. This stability is crucial for safe operations, particularly at significant heights.

Another vital component is the hoist mechanism, which enables the platform to ascend and descend smoothly along the mast. This mechanism typically relies on electric or hydraulic power, depending on the design of the MCWP. The control system, which can be operated remotely or from the platform itself, ensures that workers can operate the platform safely, managing the speed and direction of movement efficiently.

Tips: When using a mast climbing work platform, always ensure that the platform is properly secured before beginning operations. Regular inspections of the components, especially the hoist and control systems, can prevent accidents and equipment failure. Additionally, training workers on the use and safety protocols associated with MCWPs is crucial for a safe work environment.

How Mast Climbing Work Platforms Operate

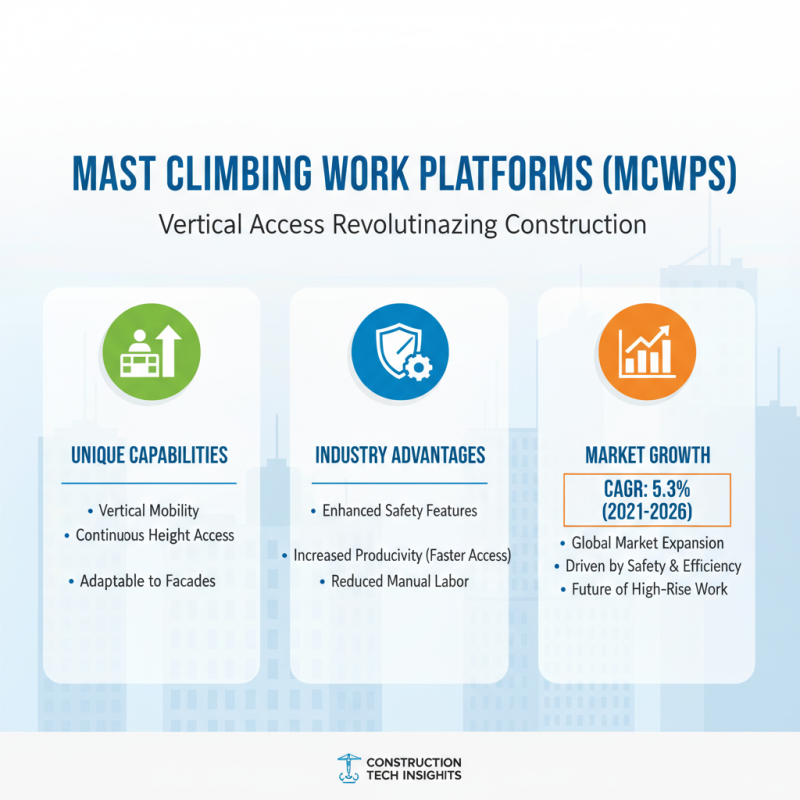

Mast climbing work platforms (MCWPs) have gained increasing popularity in the construction industry due to their unique operational capabilities and efficiency in vertical access. Unlike traditional scaffolding methods, these platforms are mounted to a mast and can move vertically along it, providing a continuous height advantage for workers. According to industry reports, the global market for MCWPs is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2021 to 2026, driven by the need for enhanced safety and increased productivity in construction projects.

The operation of mast climbing work platforms is relatively straightforward. Workers operate the platform from ground level, using a control system that allows for precise height adjustments. The platform is equipped with several safety features, such as guardrails, emergency stop buttons, and overload sensors, ensuring a safe working environment. Furthermore, the ability to carry multiple workers and materials simultaneously significantly reduces the time required for various tasks, making MCWPs a favored choice among contractors and builders.

Tips: When utilizing mast climbing work platforms, proper training for operators is essential to maximize safety and efficiency. Regular maintenance checks should also be conducted to ensure that all mechanical components, such as the mast and hoist, are in optimal condition. Additionally, always follow manufacturer guidelines to remain compliant with safety regulations, which can significantly mitigate risks on the job site.

Advantages of Using a Mast Climbing Work Platform

Mast climbing work platforms (MCWPs) have gained popularity in construction and maintenance industries due to their numerous advantages. One of the primary benefits is their enhanced safety features. MCWPs provide workers with a stable and secure working environment at varying heights. Unlike traditional scaffolding, which may require extensive assembly and disassembly, mast climbing platforms are towed up and down, reducing the risk of falls and accidents during setup.

Additionally, these platforms offer increased efficiency. The ability to move vertically at a consistent pace allows workers to access specific heights quickly without the hassle of constantly adjusting ladders or scaffolds. This not only saves time but also maximizes productivity, enabling teams to complete projects more swiftly. Moreover, the spacious platform allows multiple workers and equipment to operate simultaneously, streamlining the construction or maintenance process. Overall, the use of mast climbing work platforms significantly enhances the safety, efficiency, and effectiveness of various operations.

What is a Mast Climbing Work Platform MEWP and How Does it Work - Advantages of Using a Mast Climbing Work Platform

| Feature | Description | Advantages |

|---|---|---|

| Platform Type | Mast Climbing Work Platform (MCWP) | Stability and high load capacity |

| Operation | Vertical movement along a mast | Efficient access to high elevations |

| Safety Features | Guardrails, emergency stop buttons | Enhanced worker safety |

| Applications | Construction, maintenance, and facade work | Versatile for different projects |

| Work Environment | Indoor and outdoor use | Adaptable to various settings |

| Load Capacity | Typically up to 1,500 lbs (680 kg) | Accommodates heavy materials |

Safety Considerations for Mast Climbing Work Platforms

Safety considerations are paramount when operating a Mast Climbing Work Platform (MCWP). These platforms, which are designed to enhance efficiency in construction and maintenance tasks at height, require strict adherence to safety protocols to mitigate risks associated with working at elevation. Before commencing any work, operators should ensure that the platform is inspected thoroughly to identify any mechanical issues or damage that could compromise safety. Regular maintenance checks and adherence to manufacturer guidelines are critical in preventing equipment failure during use.

Another essential aspect of safety is proper training for all personnel involved in the operation of mast climbing work platforms. Only certified operators should handle the equipment, as they are trained to understand its functionalities and limitations. Additionally, ensuring that workers wear appropriate personal protective equipment (PPE) helps minimize the risk of accidents. Safety harnesses, hard hats, and other protective gear should be mandatory when working on these platforms. Implementing a clear communication system among crew members can further enhance safety, allowing for immediate responses to any potential hazards that may arise during operations.

Mast Climbing Work Platform Safety Considerations

Related Posts

-

Exploring Industry Trends: Mast Climbing Gear Innovations at China's 138th Canton Fair 2025

-

What is Mast Climbing Work Platforms (MEWPs) and Their Benefits?

-

Finding the Right Supplier for Best Easy Climb Mast Climbers Your Ultimate Guide to Quality and Reliability

-

Exploring Innovative Alternatives to Best Mast Climbing Work Platforms Mewps

-

A Comprehensive Comparison of Mast Climbing Work Platform Safety Features

-

Mastering Mast Climbing Gear Essential Techniques for Safety and Efficiency