10 Essential Tips for Safe Use of Raised Work Platforms You Need to Know

When utilizing raised work platforms, safety should always be a paramount concern. These versatile machines provide workers the height they need to complete jobs efficiently; however, improper use can lead to serious accidents. Understanding the essential safety tips is crucial for both operators and those working nearby to create a secure environment.

In this article, we will explore ten key tips that will help you utilize raised work platforms safely and effectively. From proper training and maintenance to utilizing appropriate personal protective equipment, these guidelines are designed to minimize risks and ensure the well-being of everyone on the job site. Whether you are a seasoned professional or new to using raised work platforms, these insights will equip you with the knowledge necessary for a safe working experience.

Importance of Understanding Raised Work Platform Safety Guidelines

Understanding the safety guidelines associated with raised work platforms is crucial for both employers and employees. According to the Occupational Safety and Health Administration (OSHA), falls are one of the leading causes of workplace injuries, accounting for nearly 33% of all fatalities in the construction industry. A thorough comprehension of safety protocols can significantly mitigate the risks associated with using these platforms. For example, proper training on how to operate the equipment safely can decrease the chance of accidents by up to 30%.

Moreover, recognizing the specific hazards linked to raised work platforms—such as electrical risks, equipment stability, and the dangers of overreaching—can further enhance workplace safety. The National Safety Council emphasizes that regular inspections and maintenance of the platforms can prevent 60% of equipment-related accidents. Understanding these guidelines empowers workers to identify potential risks and proactively address them, creating a safer work environment. Implementing these safety measures is not just a regulatory requirement but a vital investment in protecting lives and reducing associated costs due to accidents.

Pre-Operation Inspections: Key Steps Before Use

Before operating a raised work platform, conducting thorough pre-operation inspections is crucial to ensure safety and functionality. Begin by examining the platform for any visible signs of damage, such as dents, cracks, or corrosion. Pay close attention to crucial components like safety guards, controls, and harness attachment points. Checking the wheels and stabilizers for proper operation and wear is also essential, as these elements directly affect stability during use. Ensuring that all operational features are in working condition can prevent potential accidents and equipment failure.

Additionally, reviewing the worksite conditions is a critical step in pre-operation inspections. Assess the ground surface for stability and ensure it is free from obstacles, debris, or any potential hazards that could interfere with safe operation. Evaluating environmental factors, such as wind speed and weather conditions, is equally important, as these can significantly impact the safe use of raised work platforms. By implementing a comprehensive inspection routine, operators can identify and address potential issues proactively, thereby enhancing overall safety and efficiency during work tasks.

Proper Training and Certification for Operators

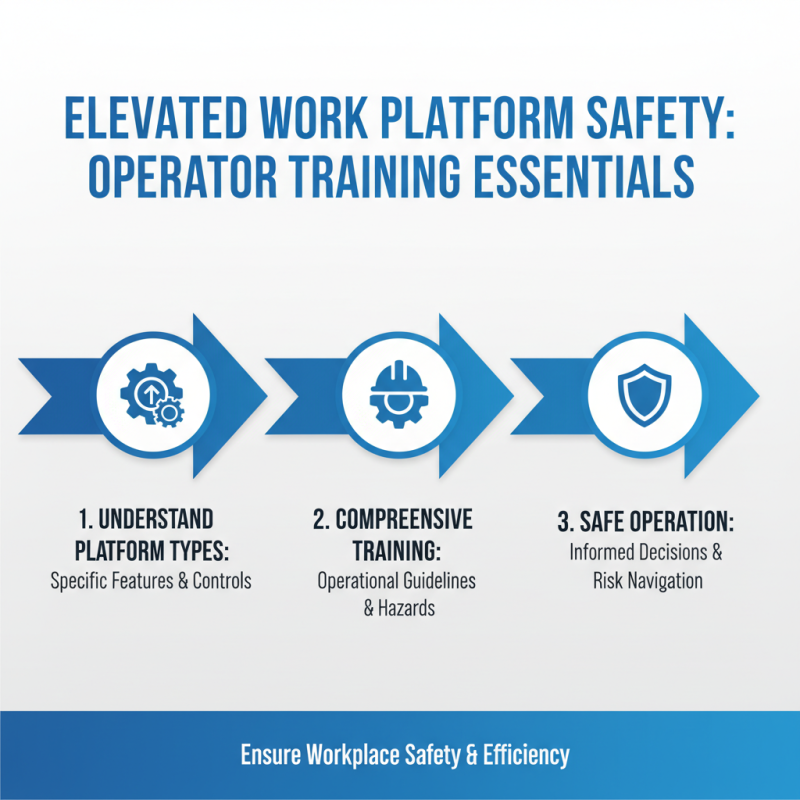

Proper training and certification for operators of raised work platforms is crucial for ensuring workplace safety and efficiency. One of the primary steps in this process is to ensure that operators fully understand the specific types of platforms they will be using, as each model may have unique features and control mechanisms. Comprehensive training programs should cover not only the operational guidelines but also the potential hazards associated with elevated work environments. This knowledge empowers operators to make informed decisions and navigate the equipment safely.

Certification processes typically involve both theoretical and practical components. Operators should be assessed on their understanding of safety regulations, equipment functionality, and emergency procedures. Simulated scenarios during training can prepare operators to react appropriately in case of malfunctions or unexpected situations. By investing in thorough training and certification, employers can significantly reduce the risk of accidents, foster a culture of safety, and ensure that all operators are equipped with the necessary skills to perform their tasks safely and effectively.

Best Practices for Maintaining Stability and Balance

Ensuring stability and balance while using raised work platforms is crucial for safety and efficiency in any project. One of the fundamental practices is to always inspect the work platform before use, checking for uneven surfaces or potential obstructions that could affect stability. Setting up the platform on solid, level ground minimizes the risk of tipping and enhances the overall safety of operations. If slopes or uneven terrains cannot be avoided, using stabilizers or outriggers can provide additional support and stability.

Additionally, users should be trained in proper weight distribution and load limits. Overloading a platform not only compromises its stability but also poses significant risks to the operator and surrounding workers. Always ensure that tools and materials are securely stored and evenly distributed across the platform. Regularly communicate with team members while operating the platform to maintain awareness of movements and any potential hazards. Implementing these best practices not only helps maintain balance but also promotes a culture of safety within the workplace.

Emergency Procedures for Accidents or Equipment Failures

Emergency procedures are critical when using raised work platforms, as the Occupational Safety and Health Administration (OSHA) reports that falls account for approximately 39% of all fatalities in the construction industry. Having a clear and well-structured emergency response plan can significantly mitigate risks associated with accidents or equipment failures. This includes training workers to recognize hazardous situations, conducting regular safety drills, and ensuring that emergency equipment, like harnesses and first aid kits, is readily accessible.

In the event of an accident or equipment failure, swift action is essential. Workers should be trained to assess the situation and communicate effectively to emergency responders. This involves having a designated safety officer who is familiar with the work site and can provide vital information about the incident, such as equipment type and the nature of the emergency.

Furthermore, the American National Standards Institute (ANSI) emphasizes the importance of conducting post-incident reviews to identify the causes and develop strategies to prevent future occurrences. By prioritizing comprehensive training and clear communication channels, companies can create a safer work environment while adhering to industry safety standards.

Related Posts

-

Top Mobile Elevated Work Platform Manufacturers in China at the 137th Canton Fair

-

Championing Excellence in Mobile Elevated Work Platforms Made in China

-

What is the Advantage of Using the Best Mast Climbing Platform for Construction Efficiency

-

Exploring Innovative Alternatives to Best Mast Climbing Work Platforms Mewps

-

Innovative Examples of Climbing Platforms Enhancing Safety and Efficiency in Industrial Applications

-

Exploring Unique Alternatives to Mobile Elevated Platforms for Enhanced Productivity