Transforming Construction with Best Mast Climber Scaffold Technology Trends for 2025 and Beyond

As the construction industry strides into 2025 and beyond, the integration of advanced technologies is becoming crucial for enhancing productivity, safety, and overall project efficiency. One of the standout innovations in this realm is the Mast Climber Scaffold, a system that is revolutionizing vertical access for construction projects. According to a report by MarketsandMarkets, the global scaffolding market is projected to reach USD 8.9 billion by 2025, with significant contributions from modular and mast climbing systems due to their versatility and efficiency. The Mast Climber Scaffold offers unparalleled benefits, including reduced labor costs and increased worker safety, which are essential as the industry faces challenges like labor shortages and heightened safety regulations. As we delve into the trends shaping this technology, it becomes clear that embracing these innovations will be vital for construction companies aiming to remain competitive in a rapidly evolving landscape.

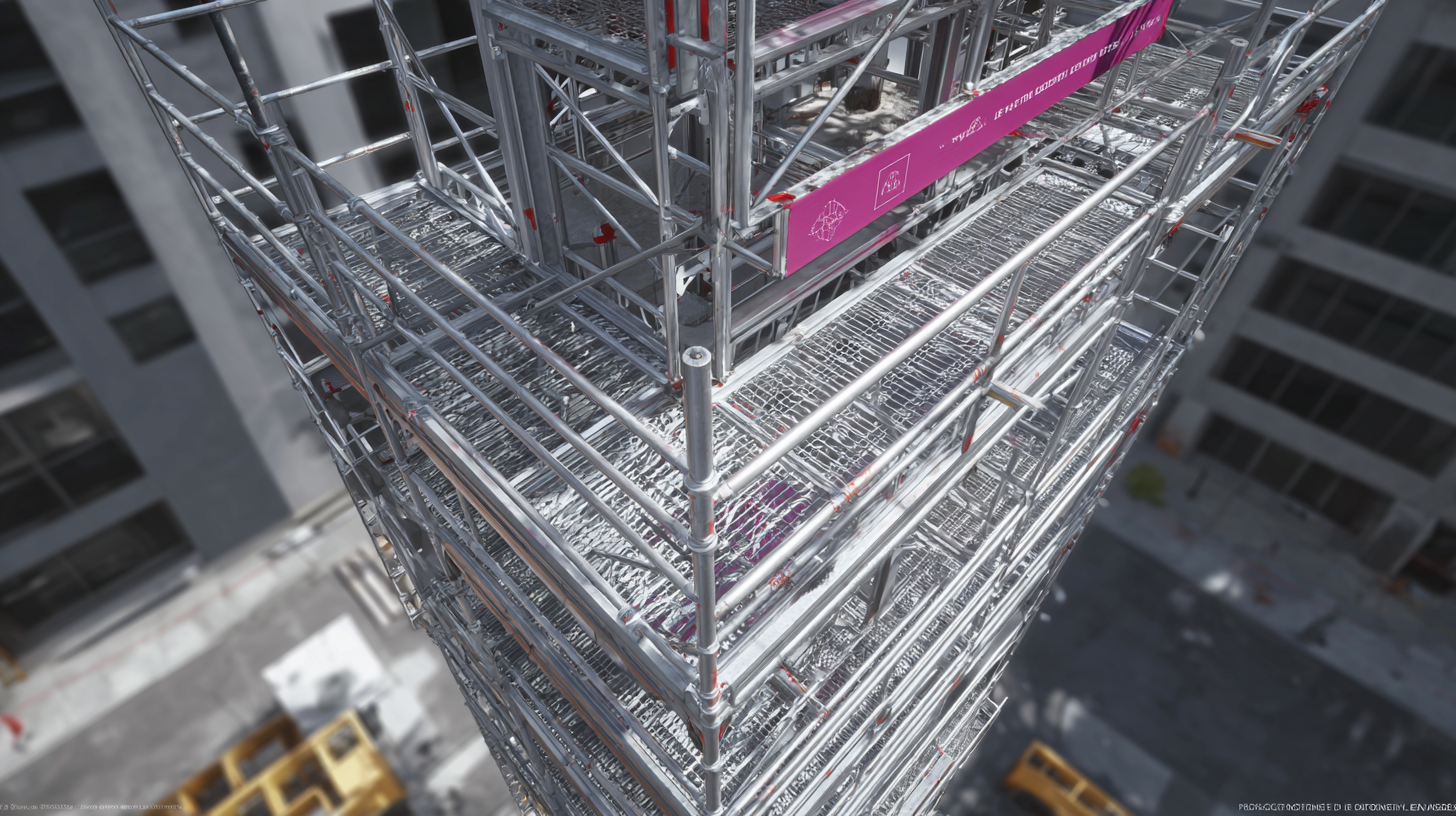

Innovative Features of Modern Mast Climber Scaffold Technologies

The construction industry is poised for significant transformation, particularly through the adoption of modern mast climber scaffold technologies that emphasize safety, efficiency, and sustainability. Recent industry reports indicate that the global scaffolding market is expected to reach $14.8 billion by 2025, with mast climbers being one of the fastest-growing segments due to their versatility and enhanced operational capabilities. These systems provide robust support for various construction activities, enabling quicker project completion while minimizing the risk of accidents on site.

Modern mast climber scaffold technologies feature innovative advancements such as automated leveling, remote control operations, and load monitoring systems. These enhancements not only streamline the assembly and disassembly process but also improve worker safety by allowing real-time feedback on potential hazards. According to a report by Smith & Associates, integrating smart technology into scaffolding solutions has led to a 30% reduction in workplace accidents over the past three years. As construction managers increasingly prioritize safety and efficiency, the demand for these advanced mast climber systems is on the rise, setting a promising trajectory for the industry heading into 2025 and beyond.

Transforming Construction with Best Mast Climber Scaffold Technology Trends for 2025 and Beyond - Innovative Features of Modern Mast Climber Scaffold Technologies

| Feature | Description | Expected Benefit | Implementation Timeline |

|---|---|---|---|

| Electric Drive Systems | Utilizing electric motors for powering mast climbers, providing a greener alternative. | Reduced carbon footprint and lower operational costs. | 2025 |

| Smart Sensors | Integration of sensors for real-time monitoring of load and operational efficiency. | Enhanced safety and optimized performance. | 2024-2025 |

| Modular Design | Scaffolding systems that can be easily assembled and reconfigured. | Improved flexibility and reduced assembly time. | 2025 |

| Remote Control Operation | Control of mast climbers via mobile devices or remote consoles. | Increased operational convenience and safety for operators. | 2024 |

| Enhanced Load Capacity | Development of systems capable of handling heavier materials. | Increased efficiency in material handling. | 2025 and Beyond |

Identifying the Right Scaffold Type for Different Construction Projects

The construction industry is on the brink of transformation as new scaffold technologies emerge to enhance safety and efficiency. Understanding the right scaffold type is crucial for varied construction projects, as improper scaffolding can lead to catastrophic incidents. Recent statistics underscore the gravity of this issue; the construction sector consistently ranks high in rates of fatalities and injuries, a reality highlighted by a tragic scaffolding collapse at a Port Arthur LNG site, which resulted in multiple fatalities. This emphasizes the need for robust scaffolding systems that can withstand axial forces, especially in challenging measurement conditions where accurate data is essential for safety.

Moreover, advancements in Building Information Modeling (BIM) have paved the way for digital tools that integrate safety risk libraries directly into the construction planning process. These innovations allow for early identification of potential hazards associated with scaffold use, significantly reducing the likelihood of accidents. Computer vision applications are also being leveraged to monitor unsafe behavior in real-time, thereby providing another layer of safety assurance.

As the industry shifts towards more automated and data-driven approaches, selecting the appropriate scaffolding type will not only enhance project efficiency but also protect the invaluable lives of workers on site.

Benefits of Using Mast Climbers in Urban Construction Environments

Mast climber scaffolds are rapidly gaining popularity in urban construction environments due to their significant advantages. One of the primary benefits of using mast climbers is their ability to enhance safety and efficiency on construction sites. Unlike traditional scaffolding, mast climbers provide a stable and secure platform that can be easily elevated to any required height, allowing workers to focus on their tasks without the worry of unstable footing. This technology minimizes the risks associated with working at heights and provides better access to the job site.

**Tip:** When selecting a mast climber for your project, ensure it has a robust safety system, including emergency brakes and reliable load monitoring. This will not only protect your workers but also enhance productivity by reducing downtime due to safety concerns.

Additionally, mast climbers can facilitate quicker construction timelines. They can move materials up and down efficiently, reducing labor costs and increasing the speed of construction processes. Their adaptability makes them ideal for urban environments where space is often limited. With the ability to navigate complex site layouts, mast climbers can be positioned to optimize work flow.

**Tip:** Always assess the site layout before installation. Planning the mast climber’s placement in advance can improve access and workflow, ultimately leading to a smoother construction process.

Safety Standards and Regulations for Mast Climber Scaffolds

In the ever-evolving construction industry, the importance of adhering to safety standards and regulations for mast climber scaffolds cannot be overstated. Recent tragic incidents, including a scaffolding collapse in Charlotte that resulted in three fatalities, underscore the dire need for compliance and rigorous safety practices. Investigations revealed that the involved companies had violated established safety regulations, highlighting a critical gap in adherence to safety protocols. According to the Occupational Safety and Health Administration (OSHA), falls from elevation account for approximately 81% of all fatalities in the construction sector, making it imperative for companies to prioritize the implementation of effective safety measures.

As we look forward to 2025 and beyond, the incorporation of advanced technology in mast climber scaffolding presents a promising avenue for enhancing safety and operational efficiency. Innovations such as automatic leveling systems and real-time monitoring of load capacities can significantly mitigate risks associated with scaffolding use. Furthermore, staying updated with safety standards is essential for contractors to not only ensure the safety of their workforce but also to avoid hefty fines and legal repercussions resulting from safety violations. The construction industry must leverage these technological advancements to protect workers and foster a safer working environment.

Maintenance Tips for Longevity and Efficiency of Scaffold Systems

Scaffold systems play a vital role in modern construction, providing essential support for workers and materials. To ensure longevity and efficiency, regular maintenance is crucial. According to the Scaffold and Access Industry Association (SAIA), improper maintenance can lead to up to 30% of scaffold-related accidents, underscoring the importance of adherence to maintenance protocols. Regular inspections should be conducted, focusing on wear and tear, loose fittings, and structural integrity. Implementing a preventative maintenance schedule can significantly reduce risks and enhance performance.

Scaffold systems play a vital role in modern construction, providing essential support for workers and materials. To ensure longevity and efficiency, regular maintenance is crucial. According to the Scaffold and Access Industry Association (SAIA), improper maintenance can lead to up to 30% of scaffold-related accidents, underscoring the importance of adherence to maintenance protocols. Regular inspections should be conducted, focusing on wear and tear, loose fittings, and structural integrity. Implementing a preventative maintenance schedule can significantly reduce risks and enhance performance.

In addition to routine inspections, training workers on proper scaffold usage and maintenance practices is imperative. The Occupational Safety and Health Administration (OSHA) reports that scaffolding accidents account for about 50 fatalities annually in the construction industry. By fostering a culture of safety and responsibility, construction firms can improve not just the lifespan of their scaffolding systems but also the overall safety of job sites. Utilizing technology, such as digital inspection tools and maintenance tracking software, can facilitate timely repairs and ensure compliance with industry standards, ultimately leading to more efficient construction processes.