How to Choose the Right Mobile Elevated Work Platform Types?

Choosing the right Mobile Elevated Work Platform Types is critical for workplace safety and productivity. The global market for these platforms is projected to reach $12 billion by 2025, with an annual growth rate of 6.5%. Increasing demand in construction and maintenance sectors highlights their importance. Electric and diesel variants each serve specific needs and environments.

However, selecting the right type can be challenging. Factors like platform height, indoor or outdoor use, and weight capacity must be considered. Mistakes in selection can lead to accidents, waste of resources, and project delays. Industry reports indicate that improper equipment choice contributes to 20% of workplace injuries.

Understanding these platforms is not just about function; it's about ensuring safety and efficiency in operations. Balancing performance with safety ratings can also be difficult. Often, operators need training to navigate these choices effectively. Reflecting on these factors ensures better decision-making and safer worksites.

Understanding Mobile Elevated Work Platforms (MEWPs)

Mobile Elevated Work Platforms (MEWPs) are essential for safe elevation in various industries. They provide a safe environment for workers operating at heights. According to a report by the International Powered Access Federation, MEWPs can reduce falls from heights by about 70%. Understanding different types of MEWPs is crucial for optimizing safety and efficiency.

Choosing the right MEWP involves considering several factors, including platform height, weight capacity, and terrain type. Scissor lifts are ideal for flat surfaces, while boom lifts can reach over obstacles. It’s important to analyze job site conditions before selecting. A poorly chosen platform can lead to increased risks and inefficiencies.

Tips: Always conduct a thorough risk assessment. Training operators on the specific MEWP is vital. Inspect equipment regularly to ensure safety compliance. Remember, a well-informed choice makes a significant difference. Missing these steps can lead to accidents and project delays. MEWPs should enhance productivity, not hinder it.

Types of Mobile Elevated Work Platforms and Their Applications

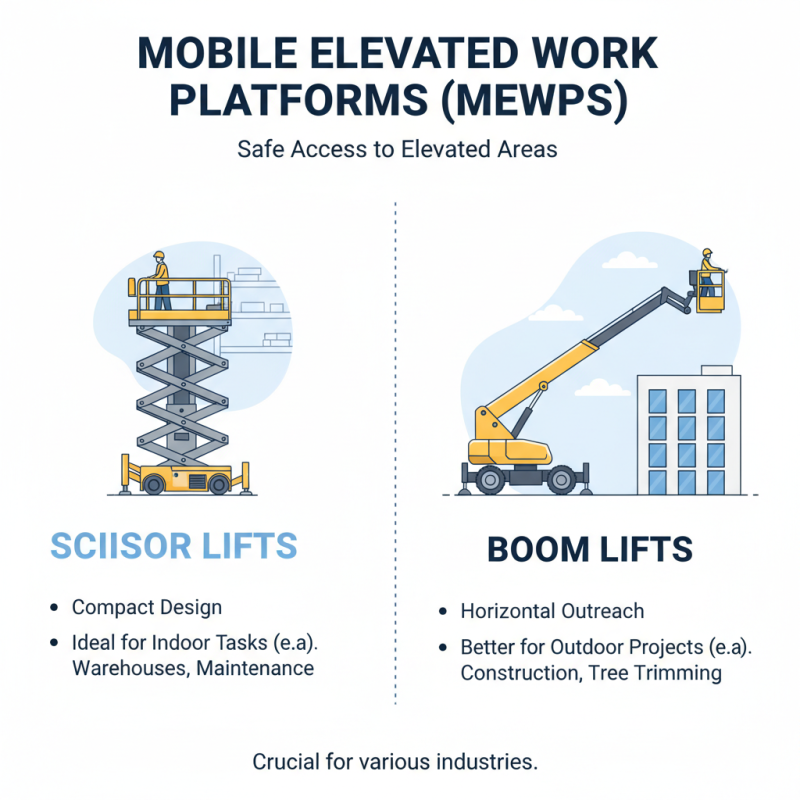

Mobile Elevated Work Platforms (MEWPs) play a crucial role in industries requiring safe access to elevated areas. These platforms come in various types, each designed for specific applications. For instance, scissor lifts are ideal for indoor tasks due to their compact design, while boom lifts are better suited for outdoor projects needing horizontal reach.

According to industry reports, the MEWP market was valued at approximately $10 billion in 2022 and is expected to grow significantly. However, choosing the right type can be tricky. A lack of understanding about the different types can lead to improper equipment usage. For example, many operators misuse vertical lifts for tasks that require lateral reach, resulting in safety risks.

While articulating the advantages of different MEWPs, it’s important to remember limitations. Not all models fit through narrow doorways. Weather can affect the performance of outdoor lifts. Operators must be trained adequately, or they may overlook safety checks. This oversight can lead to accidents or equipment damage. Each choice comes with unique benefits and potential drawbacks, impacting operational efficiency.

Key Factors to Consider When Choosing a MEWP

Choosing the right Mobile Elevated Work Platform (MEWP) involves several key considerations.

First, assess the work environment. Are there tight spaces? Will the platform access rough terrain? Understanding the location's constraints helps determine the appropriate type. Some platforms are better for indoor use, while others excel outdoors.

Another crucial factor is the height requirement. Knowing the maximum elevation needed can narrow down options. If the work involves extensive ceilings or towers, a suitable option is essential. Consider the load capacity as well. Will the platform support tools and multiple workers? It's vital to ensure safety and efficiency by matching the load needs.

Lastly, training and ease of use should not be overlooked. Some platforms are complex and require extensive training. This can hinder productivity. Simpler models might be more appropriate in such cases. Always reflect on past experiences when selecting. Was the previous choice effective? Did it meet needs without complications? That reflection can guide better future decisions.

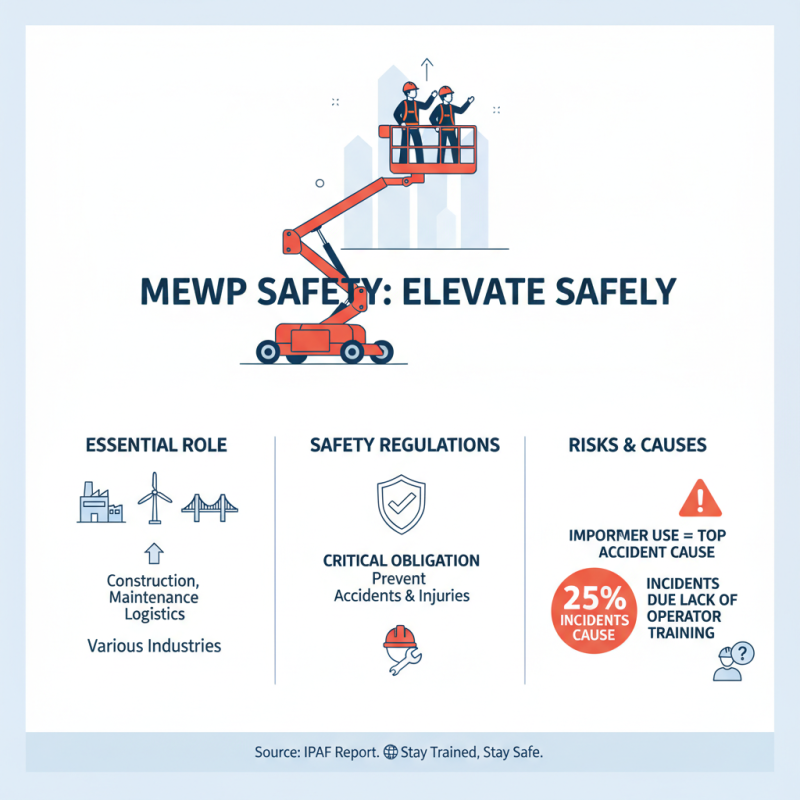

Safety Regulations and Compliance for MEWPs

Mobile Elevated Work Platforms (MEWPs) play an essential role in various industries. However, with their use comes the critical obligation to adhere to safety regulations. Compliance with these safety standards helps prevent accidents and injuries. According to a report from the International Powered Access Federation (IPAF), improper use of MEWPs is among the top causes of workplace accidents. One study showed that around 25% of MEWP-related incidents occur due to a lack of operator training.

Regulations vary by country, but many share common requirements. Operators must undergo specific training and certification. The American National Standards Institute (ANSI) emphasizes that operators must be familiar with both the equipment and the work environment. Additionally, regular maintenance checks are necessary. Failing to follow these guidelines can have severe consequences. Workers may be exposed to risks such as falls or electrocutions.

Employers must create a culture of safety. An eye-opening statistic reveals that 80% of MEWP accidents could be avoided with proper training and awareness. It’s crucial for organizations to assess their safety practices periodically. Continuous reflection on compliance measures can lead to the identification of gaps. After all, the cost of non-compliance can be substantial, impacting both human lives and business operations.

Maintenance and Training for Effective MEWP Use

When using Mobile Elevated Work Platforms (MEWPs), proper maintenance and training are crucial for safety and efficiency. According to industry reports, approximately 75% of MEWP accidents are linked to inadequate training or maintenance issues. Regular inspections can help prevent mechanical failures that lead to injuries. It's essential to address minor issues before they escalate.

Tips for Effective Maintenance: Schedule routine checks based on manufacturer guidelines. Focus on hydraulic systems, electric components, and safety features. Document every inspection, noting potential problems for future reference.

Training is equally important. Workers must understand MEWP operations and safety protocols. Hands-on training sessions enhance comprehension and retention. Research indicates that organizations with comprehensive training programs reduce accident rates by over 30%. Always assess employees' understanding; periodic refresher courses can fill knowledge gaps.

Tips for Training: Use simulations to mimic real-life scenarios. Encourage questioning during sessions. Create a culture of safety that empowers workers to voice concerns about possible equipment issues or unsafe practices. Addressing these areas can foster a safer, more effective work environment.

How to Choose the Right Mobile Elevated Work Platform Types? - Maintenance and Training for Effective MEWP Use

| MEWP Type | Max Working Height (ft) | Platform Capacity (lbs) | Ideal Use Case | Maintenance Frequency | Training Requirement |

|---|---|---|---|---|---|

| Articulating Boom Lift | 50 | 500 | Construction, Maintenance | Monthly | Yes |

| Scissor Lift | 30 | 1000 | Warehouses, Stockrooms | Quarterly | Yes |

| Telehandler | 55 | 2500 | Heavy Lifting, Construction | Bi-annual | Yes |

| Vertical Mast Lift | 20 | 500 | Maintenance, Light Construction | Monthly | Yes |

| Spider Lift | 100 | 550 | High-Rise Work, Landscaping | Annual | Yes |

Related Posts

-

2026 Best Mobile Aerial Platform Options for Efficiency and Performance?

-

Championing Excellence in Mobile Elevated Work Platforms Made in China

-

10 Essential Tips for Safe Use of Raised Work Platforms You Need to Know

-

Top Mobile Elevated Work Platform Manufacturers in China at the 137th Canton Fair

-

What is the Advantage of Using the Best Mast Climbing Platform for Construction Efficiency

-

Exploring Unique Alternatives to the Best Mobile Elevated Work Platform Options